JB/T8810.1-1998

DRB-P SERIES ELECTRIC PUMP

使 用 说 明 书

OPERATING INSTRUCTION

上海永护实业有限公司

Shanghai Yonghu Industrial Co., Ltd

(本公司通过ISO9001质量管理体系认证)

1. 用途概述 Main Application

本系列电动润滑泵是一种高压柱塞泵,适用于集中润滑系统。作为系统供送润滑剂的输送装置,既可以用于智能集中润滑系统,也可以用于单线递进式集中润滑系统。

This series of electric lubrication pumps is a kind of high pressure piston pump, apply to centralized lubrication systems, as a transportation for lubricant .Can be used in both single-line centralized lubricating system and two-line centralized lubricating system.

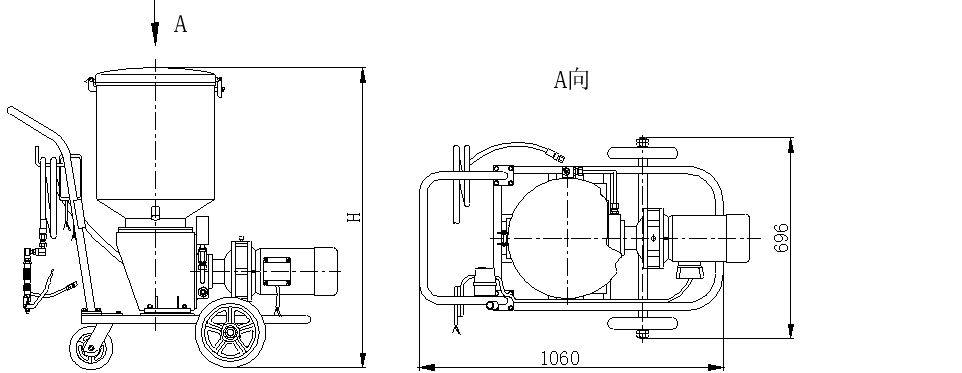

图示电动润滑泵配备了移动小车,高压输油胶管、注油枪及电缆等装置,适用于润滑点分散,要求给油压力高、给油量大,不便于采用集中润滑的场合。

The electric lubrication pump in right picture equipped with a travelling vehicle, a high pressure oil hose, grease gun and cable, etc. Apply to the occasion lubricating pointsare dispersed, asked to high pressure, large amount of grease, do not facilitate the centralized lubricating.

本系列电动润滑泵的特点是输出压力高,能够输送高粘度的润滑脂,体积小、寿命长、维修方便,而且具有双重超压保护及储油器油位自动报警功能。

The advantages about this series of electric lubrication pumps is high output pressure, can transport grease of high viscosity, small volume, long service life, convenient maintenance, and has the dual overpressure protection, the oil storage alarm automatically.

2. 技术规格 Technical Specification

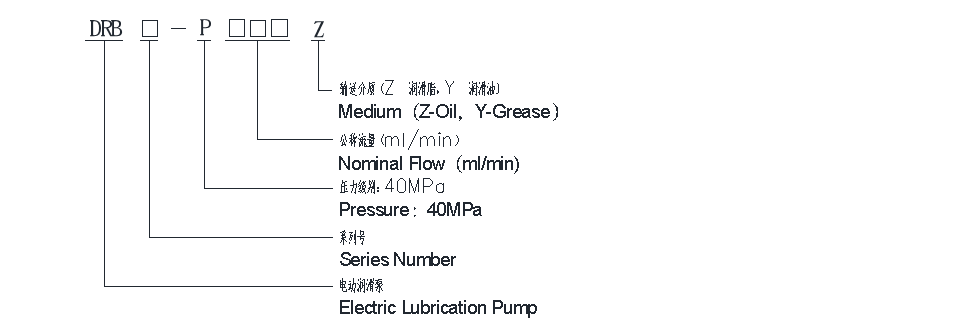

2.1 型号说明 Model Description

2.2 技术参数 Technical Parameter

表格1 Table 1

型号 Model | 公称压力 Nominal Pressure MPa | 公称流量 Nominal Flow ml/min | 储油桶容积 Volume L | 减速电机 Motor Slowdown | 环境温度 Ambient Temperature ℃ | 重量 Weight kg | |

功率 Powe kw | 电压 Voltage V | ||||||

DRB1-P120Z | 40(P) | 120 | 30 | 0.37 | 380 | 0~80 | 71 |

DRB2-P120Z | 0.75 | -20~80 | 76 | ||||

DRB3-P120Z | 60 | 0.37 | 0~80 | 76 | |||

DRB4-P120Z | 0.75 | -20~80 | 81 | ||||

DRB5-P235Z | 235 | 30 | 1.5 | 0~80 | 80 | ||

DRB6-P235Z | 60 | 85 | |||||

DRB7-P235Z | 100 | 92 | |||||

DRB8-P365Z | 365 | 60 | 85 | ||||

DRB9-P365Z | 100 | 92 | |||||

适用介质为锥入度不低于220(25℃,150g)1/10mm的润滑脂(NLGI0#-3#)和粘度等级大于

N68的润滑油。

Applicable medium : grease(NLGI 0#~2#), cone penetration≥260(25℃,150g)1/10mm, lubricating oil which viscosity ≥ N68 .

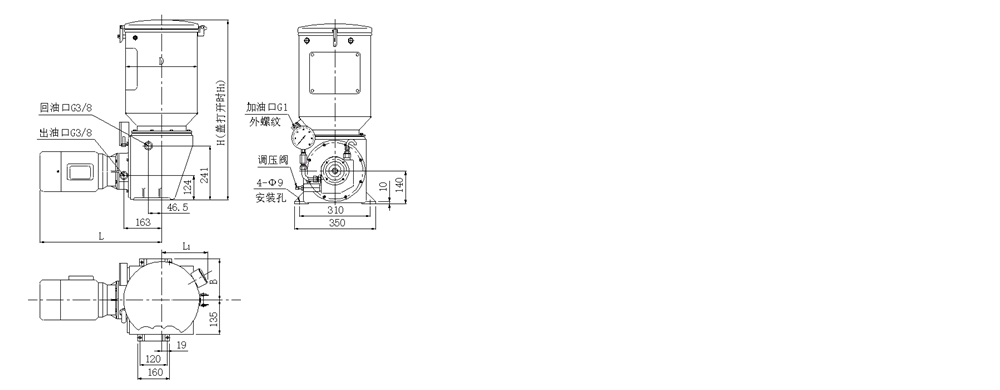

3. 外形及安装尺寸 Outline And Installation Dimension

图 1 Drawing 1

表格2 Table 2

规格 model | 尺寸 measurements (mm) | ||||||

D | H | H1 | B | L | L1 | ||

储油器 storage device | 30L | 310 | 760 | 1080 | 200 | —— | 200 |

60L | 400 | 830 | 1250 | 230 | —— | 240 | |

100L | 500 | 950 | 1450 | 280 | —— | 280 | |

减速电机 motor slowdown | 0.37kw,80r/min | —— | —— | —— | —— | 458 | —— |

0.75kw,80r/min | —— | —— | —— | —— | 498 | —— | |

1.5kw,160r/min | —— | —— | —— | —— | 558 | —— | |

1.5kw,250r/min | —— | —— | —— | —— | 558 | —— | |

图 2 移动式电动润滑泵装置

Drawing 2 Mobile electric lubrication pump device

图 3 固定式电动润滑装置

Drawing 3 fixed electric lubrication pump device

固定式电动润滑装置用于双线润滑系统中,出厂时DBR-P型电动润滑泵及24FJF-M型二位四通阀已配好管,现场安装时只需要将两条主管路与换向阀出口接管焊接即可。

Fixed electric lubrication pump device only used in two-line lubricating system, the pipe DBR-P model electric lubrication pump and 24FJF-M model two-position four-way valve use is prepared in our factory. When field installation, it only need we weld the two competent pipes and the out opening of two-position four-way valve together.

表格3 Table 3

储油桶容积 | 电 机 | |||||

30L | 60L | 100L | 0.37kw | 0.75kw | 1.5kw | |

A | 750 | 803 | 847 | —— | —— | —— |

C | 865 | 915 | 1025 | —— | —— | —— |

H | 962 | 1012 | 1122 | —— | —— | —— |

B | —— | —— | —— | 708 | 748 | 850 |

4. 主要结构及工作原理 The main structure and working principle

电动润滑泵主要由储油器、带连接法兰的泵元件、减速电机、螺旋压油机构及储油容量指示器组成。

A electric lubricating pump is form by grease reservoir, pump flange components, reduction motor, Spiral press grease institutions and grease storage indicator.

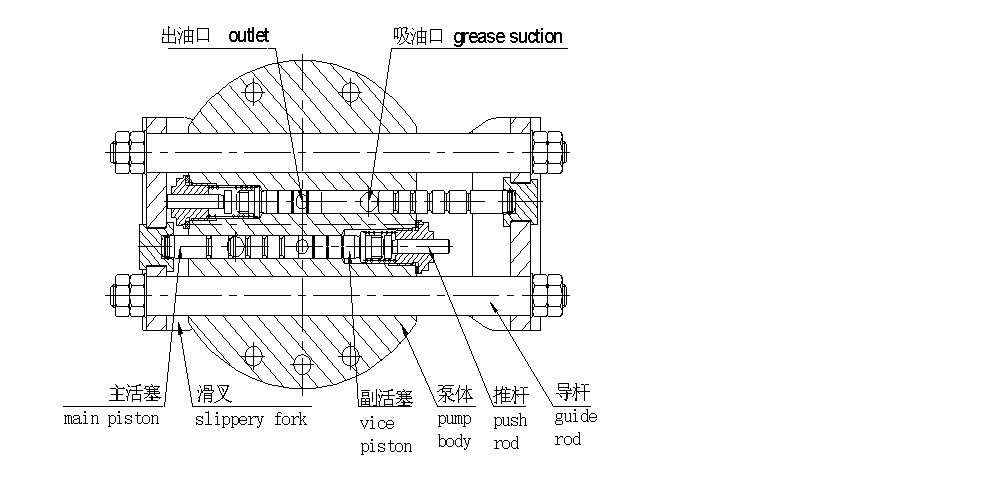

图 4 Drawing 4

减速电机及泵元件固定于连接法兰上,电机驱动偏心轴带动滑叉作直线往复运动,同时带动螺旋压油板及刮油板作顺时针旋转(润滑介质为润滑油时无此结构),经搅动变软的润滑脂均匀地被压到泵元件的吸油口周围。

Reduction motor and pump component fixed in connecting flange, motor driver partiality axis drive slippery fork make linear reciprocating motion, and causes spiral oil board and scrape oil board rotate clockwise(under the condition lubrication medium is oil without the structure ). After stirring the grease is soft ,and be pressed around the grease suction opening.

泵体内有二组活塞,每组由一个主活塞和一个副活塞组成,当一组活塞完成吸油过程时另一组活塞完成压油过程。如图4所示,滑叉到达右极限位置,上组活塞完成吸油过程,下组活塞完成压油过程。滑叉开始向左移动,下组活塞中副活塞在弹簧的作用下关闭出油口,主活塞和副活塞之间形成真空。在移动过程中,当主活塞超过吸油口时,润滑脂在大气压力作用下进入主、副活塞间的空腔内。滑叉移动到左极限位置,下组活塞完成吸油过程。运动过程的同时,上活塞组中的主活塞关闭吸油口,副活塞在压力作用下打开出油口,已吸入油脂在主活塞的作用下从出油口排出,上活塞组完成压油过程。滑叉右移,完成与之相反的另半个工作周期。如此周而复始的循环,二组活塞交替的将润滑剂压出,压出的润滑剂经泵元件连接法兰上的过滤器过滤后供送到系统中。

There are two groups of piston in the pump body, each group have a master piston and a deputy piston. When a group of piston complete suck grease process, another group of piston complete press grease process. See drawing 4, slippery fork to limit position of right ,the above piston group finished the suck grease process, the piston group below finished the press grease process. Slippery start moving to the left, deputy piston of below piston group closed outlet under the action of the spring .It’s vacuum between master piston and deputy piston. In the process of moving, When the master piston over grease suction mouth, grease flow into cavity between master piston and deputy piston under atmospheric pressure. Slippery fork moves to the left limit position ,the piston group below finished the suck grease process, master piston of above piston group closed the grease suction mouth, deputy piston open the outlet, the grease has been inhaled flow out by the action of the master piston, the above group of pistons finished pressing grease . Slippery fork began to move right, complete the opposite half working cycle .Like this, two groups of pistons press the grease alternately, inject into the lubrication system .

5. 安装、调试和使用 Installation, commissioning and use

5.1 润滑泵应垂直安装,布置在环境温度合适,灰尘少,便于调整、检查、维修及补脂的地方。

Pump should be installed vertically , set in the place where environmental temperature is appropriate, dust less ,convenient to adjustment, inspection, maintenance and add grease.

5.2 须使用清洁的润滑剂,含有杂质的润滑剂将会造成润滑泵故障甚至损坏。建议使用加油泵从补脂口加脂,补脂时要防止被污染。保持油脂干净对润滑泵的正常运行,延长润滑泵的使用寿命是至关重要的!

Must use clean lubricant , lubricant Containing impurities will cause lubrication pump failure or even damage , suggest using add-grease pump replenish grease from fat liquoring mouth, prevent polluted. Keep grease clean is very important for lubrication pump normal operation and extension the service life!

5.3 泵在shou次充填润滑脂前,zui好先加注适量的润滑油,以利排除空气。如果条件不允许,也可以直接注入润滑脂,但泵在运行至空气排出后才会有润滑脂排出。

At the first time for the pump filling grease, it’s better filling a moderate amount of lubricating oil , to ruled out air . If the condition is not allowed ,can also injected grease directly ,but the grease will flow out only there is no air.

5.4 调压阀的设定压力可以在0~40MPa范围内调节,调节螺钉旋入,压力升高,旋出则压力降低,使用时不允许超过泵的公称压力(40MPa)。出厂时压力已调定为40MPa。

Setting pressure of governing valve is 0~40MPa,can regulate. Adjustment screws twist into , pressure increases , opposite direction the pressure reducing . It doesn't allow higher than nominal pressure of the pump(40MPa).

5.5 由于某种原因,泵压力达到50MPa时,安全阀中的保险片会破裂,润滑脂从弯管中溢出,泵压力降为零。更换新的保险片前要查明原因,排除故障。保险片在安装时应凸面向上,只能放置一片。如凸面向下或放置两片,泵会因为压力超过允许值而损坏。

For some reason , pump pressure up to 50 MPa , rupture disc in relief valve wii rupture, the grease flow out from the bend pipe, pump pressure drops to zero .Fond the reason before replacement rupture disc, troubleshooting. Raised face up when install the rupture disc, you must only put one piece. If raised face down or put two piece, pump will over pressure and damage.

5.6 泵出油口处的过滤网应定期清洗,以防止堵塞。

Mesh nearby outlet should be clean regularly, to avoid block .

5.7 减速电机初用三个月时应从减速机排气孔中注入适量的![]() 二硫化钼润滑脂,以后每四个月补充一次。

二硫化钼润滑脂,以后每四个月补充一次。

At the first three months, should inject ![]() molybdenum disulphide grease,every four months a supplement after .

molybdenum disulphide grease,every four months a supplement after .

5.8 该系列润滑泵为室内使用型,在室外或环境恶劣的条件下使用时需采取必要的防护措施。

This series of lubrication pumps for indoor use, using outdoor or in harsh environment conditions should be necessary protective measures.

6. 故障的判断及排除方法 Fault judgment and elimination

故障 fault | 可能引起原因 Possible reasons | 排除方法Elimination method |

无压力或压 力较低 no pressure or Pressure is low

| 调压阀调定值太低 setting value of governing valve is too low | 调高压力 reset the pressure higher |

储油器内刮油板不转 Scrape grease board does not rotate | 消除不转原因 Eliminate not turn reason | |

调压阀芯活塞卡死 the piston of governing valve core is stuck | 清洗调压阀芯 Cleaning pressure regulating valve core | |

调压阀芯O形圈损坏 o-ring in governing valve core is damaged | 更换O形圈 Replacement o-ring | |

泵元件吸油口堵塞 Pump oil absorption mouth components jam | 清除堵塞物 Cleared the blockage | |

泵元件安装螺钉松动 Pump components mounting screws loose | 紧固安装螺钉 Tighten mounting screws | |

泵元件O形圈损坏 Pump components o-ring damage | 更换O形圈 Replacement o-ring | |

副活塞回位弹簧损坏 Deputy piston spring damage | 更换新的弹簧 Replace spring | |

泵元件活塞与孔磨损严重 Pump components and piston hole badly worn | 更换泵元件 Replacement pump components | |

泵元件活塞卡死 Piston of pump components stuck | ||

泵元件活塞帽脱落 Piston hat of pump components off | ||

流量小 little capacity | Pump components and piston hole badly worn | 更换泵元件 Replacement pump components |

泵元件吸油口堵塞 oil absorption mouth jam | 清除堵塞物 Cleared blockage | |

出油口滤网堵塞 Screen pack nearby outletjams | 清洗过滤网 Clean screen pack |

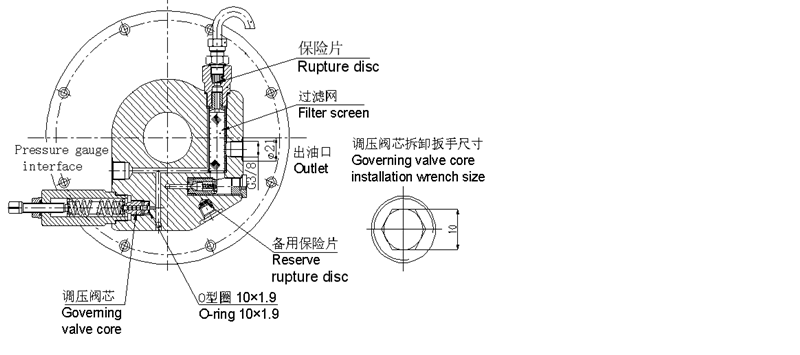

图 5 Drawing 5

图 6 Drawing 6

7. 维修 Maintenance

7.1 调压阀维修(参见图6) Maintenance governing valve (see drawing 6)

拧下调压阀外壳,旋出调压阀芯,清洗干净,观察活塞及活塞孔,如果外表光滑,活塞在孔中滑动自如,则说明调压阀芯没有损坏。如果有明显的划伤,活塞在孔中不能自如滑动,则须更换新的调压阀芯。安装时要注意:O形圈不能有任何损伤,如有损伤要立即更换,安装过程中,注意O形圈不要脱落。

Back off governing valve housing , take out governing valve core , clean it, observe the piston and the piston hole ,if the surface is smooth , piston in the hole sliding freely, governing valve core is not damage. If there is a marked scar, piston in the hole not sliding freely, must replace the governing valve core . When installation should pay attention : O-ring can't have any damage, or replaced immediately , installation process , be sure O-ring not fall off .

7.2 螺旋压油机构维修 Spiral press grease institutions servicing

首先要判断压油机构是否存在故障,判断方法为:停止润滑泵,打开储油桶盖,用手扳动垂直刮油板,如果顺时针可以转动,逆时针不能转动,则说明压油机构没有故障。润滑泵启动时刮油板不转可能是储油器内油脂太少所致,否则说明压油机构有故障。

Determine if the spiral press grease institutions is out of order. Judgment method :stop the pump ,open the cover of the barrel, move vertical grease board by hand, If clockwise rotation, don’t rotation counterclockwise, mean spiral press grease institutions is well. At the time starting pump, scrape oil board not rotation may be the grease is too little , otherwise pressure grease institutions have a fault.

取下储油桶,将压油机构拆下,检查各零部件是否有损坏,转动部分是否卡死。重新安装时,须使泵元件上的柱形销处于离合器摆杆槽内(参见图五)。判断方法同上。

Remove the oil storage tank, remove the oil pressure mechanism, check whether the parts are damaged or not, and whether the rotating part is jammed. When reinstalling, the cylinder pin on the pump element must be in the clutch swing bar (see Figure five). Ditto the method of judgment.

7.3 泵元件维修 Pump components maintenance

松开四只M6×50内六角螺钉(GB70-85),将泵元件整体取下,注意定位销、销套及O形圈不要脱落。清洗干净,检查各零件是否有损坏。如果活塞、活塞孔有划伤或严重磨损,则须更换新的泵元件。安装时注意:1)活塞与活塞孔是选配的,不能搞错;2)滑块带油槽的两面与滑叉槽配合;3)定位销、销套及O形圈不要脱落;4)四只螺钉的紧固力要均匀;5)柱形销须装入离合器摆杆的槽内。

Loosen all four M6 x 50 hex screws (GB70-85),take off the whole pump components, notice positioning pin, pin set and o-ring don't fall off. Clean them, check the parts for damage. If the piston, piston hole have wounds or serious wear , must replace the pump components. When installation, attention : 1)the piston and piston hole is matching , don’t be mistake , 2) The two sides of slider with oil groove, cooperates with slide fork groove .3)positioning pin, pin set and o-ring not fall off ,4) Four screws stress evenly, 5) Cylindrical pin must be put in the swinging rod slot of clutch.

2. 随机备件 Spare parts

名称 name | 数量 quantity | 安装部位 Installation position | |

1 | O形密封圈 12×1.9 O-Ring 12×1.9 | 2 | 泵元件与法兰油道连接处Pump components and flange joint place |

2 | O形密封圈 10×1.9 O-ring 10×1.9 | 2 | 调压阀芯 Governing valve core |

3 | 副活塞回位弹簧 Vice piston return spring | 2 | 泵元件 Pump components |

4 | 保险片 Rupture disc | 10 | 安全阀 Relief valve |